About

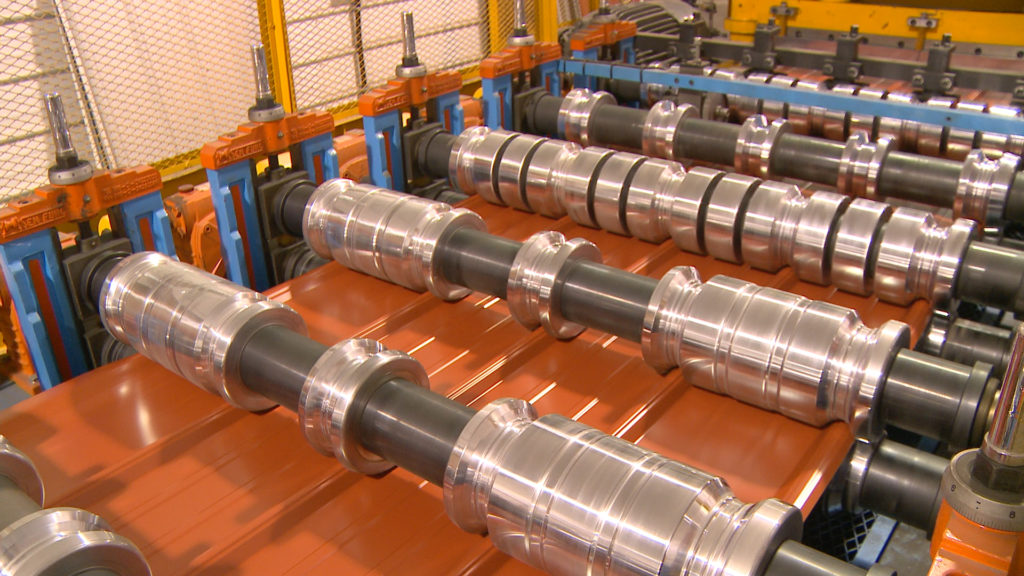

Located in the heart of South Dakota, Fordham Manufacturing is a locally owned and operated manufacturing facility which rolls and forms sheet metal used for agricultural, commercial and residential buildings. Our success is driven by our commitment to providing our customers with unmatched service and quality, on time, every time. Our state of the art facility is equipped with sophisticated equipment; we can provide every cut, angle and size on time, damage free.

What makes Fordham Manufacturing unique? We sell directly from our facility to our customers. By eliminating the middleman, we provide our customers with quality products at a lower price than others. Our team of experienced professionals are able to assist you throughout all stages of your project.

Delivery available Monday – Sunday.

Terms

Unless credit has been arranged, all orders will require a deposit prior to any manufacturing.

Quotes

Material quotations provided will be good for a period of 30 days, unless otherwise stated. Quotations will be F.O.B. the manufacturing branch unless delivery to another location or site has been agreed upon in writing. Customer/end user is responsible for signing off and confirming all sheet lengths etc. when ordering. Fordham Manufacturing will not be responsible for incorrect sheet lengths and quantities on confirmed order form.

Delivery

Fordham Manufacturing. may be able to arrange shipping on orders. Call for pricing and freight availability. Method of offloading all material on site or at destination is required to be supplied by the customer or end user.

Return Policy

Fordham Manufacturing. will not accept the return of custom rolled sheets or custom flashing. Accessories may be returned at the discretion of Fordham Manufacturing, a 20% restocking fee will be applied to all accessory returns. Open packages of fasteners will not be accepted for return.

Handling

Proper handling of steel cladding bundles should be taken to prevent kinking, bending or scratching of steel panels. Failure to do so could result in damage to materials or bodily harm. Fordham Manufacturing is not responsible for bodily harm or damage to materials due to improper handling.

Manual – Proper handling should be taken to avoid bodily harm and damage to material. Gloves should be worn when handling steel sheets and rubber sole footwear should be worn if walking on roof sheets. Roof sheets can be slippery due to moisture and oils used in the production process, caution should be taken when handling or walking on steel sheets. When picking up or carrying metal roofing and siding sheets, handling should be done on the underlap edge to avoid fingermarks and small dents that can be caused by picking up the sheet on the overlap edge. If handled improperly, lifting and carrying can create a wavy appearance in the overlap edge, caused by fingers. Metal roofing and siding sheets should be carried vertically to the ground by holding the underlap edge in order to avoid buckling and kinking of the panels. Sheets over 4’ should be handled by two or more people, with one person placed every 6’ to 8’ along the panel. Never drag panels across each other as this could result in scratching of paint or coating.

Forklift – When handling bundles of steel cladding with a forklift it is important to make sure forks are at their maximum separation and bundle is secure. Open bundles should not be handled with a forklift or any machine. Proper support should be put under the length of the bundle when travelling long distances or over rough terrain. For longer bundles, a spreader bar is recommended to support the bundle when transporting or handling with a forklift.

Storage

If possible, storage should be avoided and panels should be installed upon arrival at site. If storage is unavoidable, the metal roofing and siding panels should be stored under a roof in a cool, dry, well ventilated area , off the ground. If storage outside is only the only option, then bundles should be secured and properly covered using a tarp to protect from wind and rain. It is recommended that one end of the bundle be elevated to allow any moisture to run off the panels. When choosing a tarp to cover panels make sure to use a tarp that allows ventilation and won’t allow the buildup of moisture and condensation on the panels being covered. When in storage avoid any contact of moisture or water with metal roofing and siding panels as failure to do so may result in corrosion or rusting and any warranty will be void.

Cutting Sheets

Fordham Manufacturing highly recommends the use of heavy duty turbo shears or some other form of nibbler when cutting steel panels on site. The use of saws or blades can create hot burs and filings which can embed into the paint layer and damage the surface. Hot burs and filings often rust when they come in contact with moisture, creating a rusting appearance on the surface of your steel panel. If the use of saws or blades is unavoidable, it is recommended that panels be flipped over when cutting, allowing the burs and filings to land on the backside of the panel. All burs and filings should be wiped away immediately to avoid rusting and damage to the panel. If rusting on panels is found to be caused by external burs or filings from cutting or pre drilling, any warranty on material will be void.

Pre-Drilling Sheets

Similar to cutting steel panels with a saw or blade, pre drilling stacks of metal sheets is not recommended. Pre drilling stacks of sheets will create hot burs and filings which will fall between the sheets and potentially embed into the paint layer. If not wiped away immediately these burs will rust when they come in contact with moisture and create a rusting appearance on the metal sheet before or after installation. If pre drilling stacks of sheets is required, it is highly important that the entire bundle be installed immediately and all burs and filings are wiped away. If panel rusting is found to be caused by external burs or filings such as those created when pre drilling, any warranty on material will be void.

Touchup Paint

If scratches or nicks happen to occur on the paint finish of your sheet steel, touch up paint can be used to cover up small damages. It is recommended that touch up paint be applied using a small fine brush and only applied to the affected area. Direct spraying of aerosol cans should never be attempted. Touch paint weathers at a much faster rate then the factory applied paint finish and therefore direct spraying of aerosol cans may cause a blotchy look over time.

Maintenance

In order to maintain the long term appearance of your metal roof , proper maintenance should be taken. With time, dust and dirt may build up on your prepainted steel roof or siding, or chalking may begin to occur, causing a change in appearance or apparent discoloration. Color and appearance can be restored simply by washing the roofing or siding with water by use of a hose or high pressure washer. Mild detergent can also be used to clean steel roofing and siding. Wire brushes, abrasives and strong solvents or cleaners should be avoided as they can potentially damage your steel roofing or siding. Regular removal of debris such as leaves, branches and standing water is also important in ensuring the long term appearance of your metal roofing or siding.